In addition to the pure silos, umtec also offers the associated equipment technology.

In this way, you obtain a functional plant without any interfaces and have only one contact person for the spare parts service.

Silo components

umtec BFE filters

A filter must be installed on the silo for almost every bulk material.

The filter elements installed in the BFE filter can be flowed against from below as well as from above.

In the event of relatively low dust contents of the supply air flow, the inflow from above leads to very compact units - in the event of higher dust contents, the inflow from below is advisable to protect the elements.

The regeneration of the filter elements takes place by means of compressed air and is extremely effective due to the plate-shaped arrangement. In addition, the filter elements are self-supporting throughout, so that no supporting elements can lead to mechanical wear.

Our competent staff will be pleased to provide you with further information on the umtec BFE filter and its individual application.

Go ahead and ask us about them!

umtec cartridge filters

By contrast with the filter elements in the BFE filter, the cartridge filters are almost always flowed against from below.

The regeneration of the elements also takes place using compressed air.

The main advantages of the cartridge filters are the overall more compact design of the filter and the high operating temperature of max. 260°C.

These are normally raw gas flows from thermal processes.

You would like to know more about the umtec cartridge filters? Go ahead and ask us about them!

Loader filter

The umtec loader filter is a very compact cartridge filter that is mainly used for dedusting during the loading of trucks.

Modern loading is usually realised with telescopic loaders.

The extracted dust is fed back into the product stream, meaning separate disposal is not required.

Loading devices are often installed in the periphery of systems with unfavourable ambient conditions - which is why high-quality special cartridges are used here.

You need more information about our umtec loader filters? We will be happy to advise you!

umtec STAFI

In addition to the BFE filter, there is another top filter from umtec - the STAFI.

It is always used when it is not possible to supply the silo system with compressed air.

The advantages at a glance:

- Regeneration of the filter bags by means of a vibration motor

- Increase in service life through optimum fluidic design and predefined cleaning cycles

- Simple filter bag change thanks to clip-in closure

- Use under harsh operating conditions.

Would you like to know more? Get in touch with our competent staff! We will be happy to advise you!

Silo overfill protection

The overfill protection is an autonomous system with ready-to-connect control unit to protect the silo and its components from damage and overfilling.

It consists of, among other things, a pinch valve, pressure switch and Max probe, which work together with the respective top filter.

A proximity switch automatically triggers the cleaning of the filter and opens the pinch valve when the silo vehicle is coupled and uncoupled.

By attaching a key switch in the control box and a padlock on the hand lever, the lines are also protected against foreign or incorrect filling.

On request, an additional foreign body sieve can be integrated within the filling line.

You would like to know more about our overfill protection? We are happy to inform you including in person!

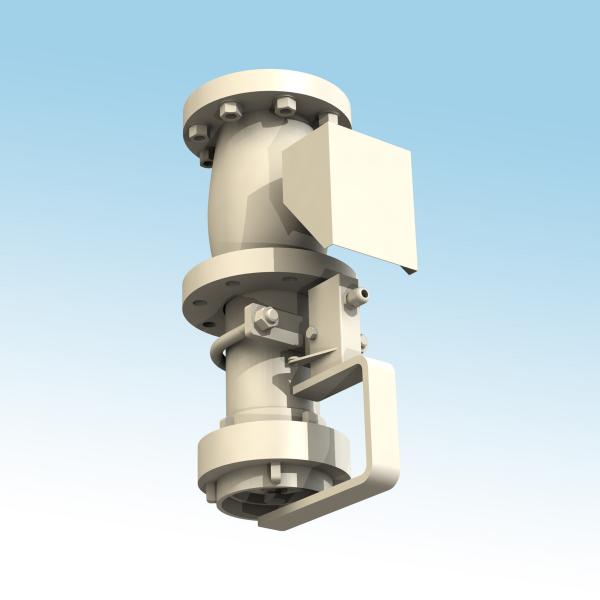

Over/under pressure flap

An over/under pressure flap acts as a balancing valve for safety and protection against destruction of the silo.

It is installed in the silo roof and can be dimensioned differently depending on the air volume.

Positive/negative pressure dampers are adjustable for different pressures and require regular maintenance.

There are various design options depending on your requirements:

- Dimensioning according to air volume

- Steel or stainless steel

- Spring-loaded or weight-loaded

- With signal transmitter

- Special designs for explosion-proof silos (requires maintenance)

You can also obtain more information about over/under pressure flaps in talks with our friendly staff. Go ahead and ask us about them!

Level measurement technology

Various measuring techniques are used to monitor the filling levels in a silo.

The built-in sensor system then either displays a signal on site or forwards it to a control centre.

Depending on the nature of the bulk material, different devices or measuring principles can be used:

- Measuring task Limit level (max./min.): e.g. capacitive limit switches, vibration limit switches or rotary vane detectors

- Measuring task Filling level: e.g. Radar sensor or ultrasonic sensor

- Ask us which solution is the right one for you. We are happy to inform you including in person.

Silo discharge aids

Additional discharge aids can be installed to ensure that materials that flow poorly also flow out of the silo cone without any problems.

This avoids downtimes and at the same time ensures a smooth production sequence.

Various options are available, which can also be combined, depending on the application and bulk material.

- Pneumatic discharge aids (nozzle air loosening, plate air loosening, hose air loosening, fluidisation floor, air cannon)

- Mechanical discharge aids (vibrating discharge floor, vibrator, vibrating basket, screw discharge floor, sliding frame)

- Structural discharge aids (silo lining)

We would be happy to hold talks with you, about what appearance a customised solution might take!

Shut-off devices

A safe closure of the silos despite a wide variety of bulk materials - ranging from dusty to coarse - is possible thanks to a wide range of shut-off devices.

These can be operated manually, electrically or pneumatically - as a rotary flap, flat damper, shell damper or simply as a flapper damper.

- Flat slide valve dusty and granular bulk materials weighing up to 80mm

- Shut-off valves for powdery bulk materials

You require more information about shut-off devices? We will be happy to advise you!